From Drum to Disaster: Crafting a Floating Perahu from Plastic Drums—A Simple, Resourceful Alternative

From Drum to Disaster: Crafting a Floating Perahu from Plastic Drums—A Simple, Resourceful Alternative

In a world where innovation meets improvisation, transforming discarded plastic drums into practical functional boats offers both sustainability and ingenuity. With bicycle inner tubes, ropes, and tarpaulin, communities facing limited materials are turning rusted drums—abundant and heavy—into sturdy flat-bottomed floating pontoics. This hands-on guide reveals how to build a reliable perahu (canoe-style boat) using plastic drums, blending local ingenuity with simple engineering to deliver affordable, eco-friendly water transport.

Plastic drums—once home to oil, dyes, or chemicals—hold hidden potential for creating lightweight yet durable marine vessels. Though initially unsuitable in raw form, these cylindrical containers become a floating foundation when properly modified. With careful cutting, reinforcing, and waterproofing, a team of local artisans and builders can assemble a perahu capable of handling daily river and lake crossings.

The process transforms waste into utility, empowering communities to overcome infrastructure gaps through creative reuse.

Step-by-Step Construction: From Drum to Functional Boat

Building a perahu from recycled plastic drums demands precision and attention to structural integrity, but the end result is accessible to builders with basic DIY skills. The process begins with collecting and cleaning drums—typically 200-liter industrial plastic barrels—then removing labels and residual contents thoroughly. Each drum serves as a single pontoic; multiple units are stacked side by side to form the hull.- Material Procurement: Reserve 8–12 clean, sturdy drums; each provides approximately 200 liters of plastic volume. Find local suppliers or repurpose used drums from factories, markets, or processing plants.

- Preparation and Cutting: Using heavy-duty cutting tools, shape the drum sides into a flat roughly rectangular frame. The usable cavity becomes the boat’s base, while edges are beveled to reduce sharpness and improve stability.

- Reinforcement and Waterproofing: Bond reinforced fiberglass mesh or synthetic mesh to internal walls for tensile strength.

Seal seams with epoxy or heat-welded plastic patches to prevent leaks. Apply UV-resistant polymer coating to protect against ocean spray and sunlight degradation.

- Attachment of Floating Modules: Attach elastic inner tubes (bicycle (or vehicle) inner tubes work best) beneath the drum frame to create buoyant pontoics. Secure connections with high-strength bungee cords or polyethylene straps, ensuring adjustability for weight distribution and balance.

- Deck and Access Features: Extend cut panels into a raised deck using tarpaulin or finished wood for comfort.

Add baked-on seating from recycled plastic bottles or repurposed materials to complete the user interface, making the boat operational and safe for passengers.

The resulting platform, though lightweight, demonstrates impressive load capacity, averaging 2–4 tons depending on drum size and reinforcement, ideal for transporting goods, small vehicles, or crew across shallow rivers and lake environments where traditional boats are impractical.

Engineering Insights: Strength, Stability, and Safety

Despite their plastic composition, repurposed drums offer significant structural benefits when properly engineered. The cylindrical shape resists deformation under weight, while submerged pontoics generate lift, enabling stable floating behavior.Each drum acts independently, minimizing disaster risk—damage to one unit doesn’t sink the entire craft. Key technical factors include:

– **Seam Reinforcement:** Mesh lining prevents stress cracks under pressure and moisture exposure.

– **Waterproof Integrity:** Epoxy sealing ensures long-term durability against rot and osmotic blistering.

– **Buoyancy Optimization:** Inner tubes deposited evenly along the frame maintain proper flotation and prevent tilting.

– **Load Distribution:** Additional fiberglass meshing reduces flex, increasing durability during rough water transit. Local builders often enhance performance by adding cross-beams between drums, reinforcing the hull, or integrating decorative yet functional raised sides to protect against spray.

Real-World Impact: Sustainable Transport Solutions

In regions struggling with fuel shortages, limited access to metal fabrication, or fragile river economies, these plastic drum perahu provide a lifeline. They emulate traditional craftsmanship while leveraging mass-waste materials, reducing environmental burden and dependency on imported boats. In one documented case from a lakeside village in Indonesia, a community of fishermen built seven perahu from recycled drums—eliminating the need for imported wooden boats and slashing transport costs by over 60%.“We used what the sea gave back,” said one builder, “now our boats sail the lakes, connecting families and markets.”

Environmental gains are compelling: repurposing plastic drums prevents plastic accumulation in waterways, turning persistent pollution into functional tools. Each perahu saves several hundred kilograms of non-biodegradable waste from decay in landfills or ecosystems. This circular economy model demonstrates how innovation thrives at the intersection of necessity and creativity.

How to Begin Your Own Projekt: Tools, Tips, and Community Resources

Starting with drifting behind plastic drums requires minimal specialized tools—just basic cutting, drilling, and bonding equipment.A hacksaw or metal shear handles drum sections; pivoting tools secure reinforced mesh and straps; UV glue or epoxy ensures lasting waterproof junctions. Local maker spaces and vocational centers often support outreach, offering shared access to fabrication tools. Beginners should:

- Start with

Related Post

Where Is Boston Located: Gateway to New England’s Historic Heart

Checkout Frenzy: The High-Pressure Race to Close the Last Deal

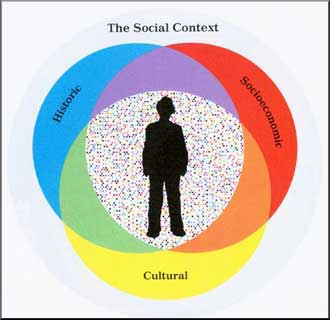

Nj Burkett & WABC Bio: Age, Height, and the Life Story of a Public Figure | Understanding a Life in Context

Top Outdoor Playgrounds: Find The Best Near You!