IIOSC Siam Silica: Your Guide To Thailand’s Silica Giant Driving Innovation and Industry

IIOSC Siam Silica: Your Guide To Thailand’s Silica Giant Driving Innovation and Industry

Thailand’s IIOSC Siam Silica stands as a cornerstone of the nation’s mineral resources, dominating the global silica market with its vast reserves, cutting-edge processing technologies, and commitment to sustainable extraction. As a subsidiary of the influential IIOSC Group, Siam Silica is not merely a supplier of industrial-grade silica but a pivotal player shaping Thailand’s manufacturing backbone, from electronics and construction to pharmaceuticals and renewable energy. Its influence extends beyond domestic markets, with strategic export networks reaching Asia, the Middle East, and beyond.

For industry leaders and investors alike, understanding IIOSC Siam Silica is essential to grasping the evolution of Thailand’s high-value materials sector.

Millions Tonel of High-Quality Silica—Siam Silica’s Underground Wealth At the heart of IIOSC Siam Silica’s dominance lies its access to some of Southeast Asia’s richest silica deposits, primarily concentrated in central and northern Thailand. The company operates mines and quarries that tap intoResources dating back millions of years, forming high-purity fused silica and fused quartz critical for semiconductor manufacturing, optical components, and advanced composites.

Geological surveys confirm that these deposits feature some of the world’s most consistent silica quality, with silica content exceeding 99.5% in select zones. This geological advantage is fortified by decades of refined extraction techniques that maximize yield while minimizing environmental disruption. The company’s operations cover over 12,000 hectares across key regions, making it one of Thailand’s largest industrial landholders in the minerals sector.

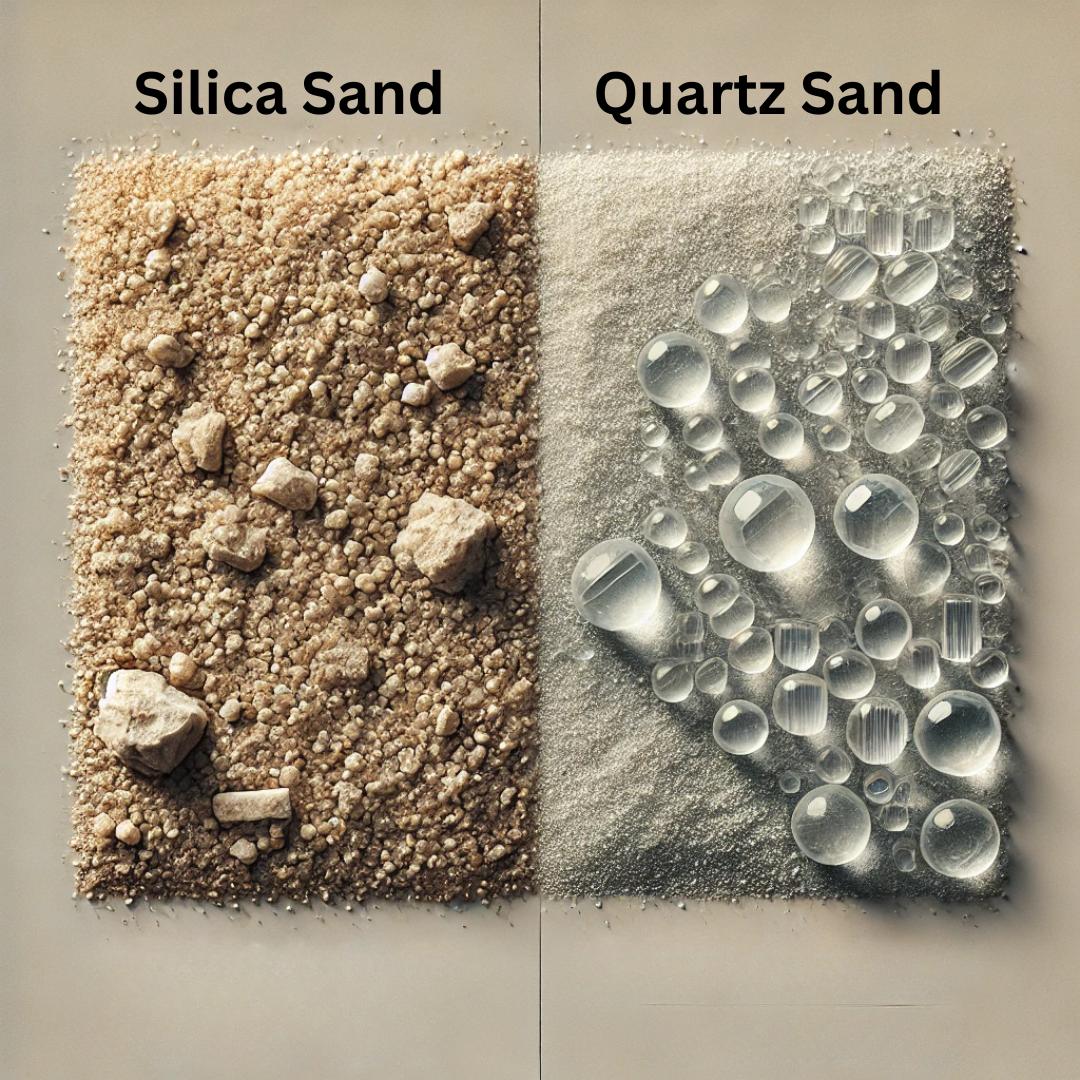

Advanced Processing: From Raw Stone to Precision Silica Transforming raw silica into market-ready materials demands precision engineering, a domain where IIOSC Siam Silica has established regional leadership. The company employs state-of-the-art crushing, grinding, and purification systems to produce silica powders, granules, and specialty phases tailored to niche industrial applications. These processes include high-pressure grinding in jet mills for ultrafine particle sizes, plasma-enhanced surface treatments to improve reactivity, and rigorous quality control via spectroscopic and thermal analysis.

“Our facilities are designed to meet global standards,” notes an internal operations report. “Each batch undergoes over 40 quality checks to ensure consistency, purity, and performance—key for clients in electronics and optics.” This blend of natural endowment and technological sophistication positions Siam Silica as a preferred supplier in high-speed, high-accuracy industries.

Strategic Alliances and Export Reach—Thailand’s Silica Bridges Asia Beyond production, IIOSC Siam Silica excels in global market integration, with export logistics spanning over 35 countries.

Regional hubs in Bangkok, Rayong, and Padang basil serve as export gateways, supporting just-in-time delivery for manufacturers in Vietnam, Malaysia, India, and even Dubai. The company partners with leading logistics providers and leverages Thailand’s deep-water ports to maintain supply chain resilience. Notable clients include semiconductor giants, solar panel manufacturers, and medical device producers who rely on Thailand’s silica for precision components.

“We don’t just ship silica—we deliver value through traceability and reliability,” states a senior export manager. “Our data shows 98% customer retention, driven by consistent quality and responsive service.” Such behind-the-scenes coordination underscores the company’s role as a strategic node in Asia’s industrial supply chain.

Sustainability and Innovation: Future-Proofing Thailand’s Silica Industry Recognizing growing environmental scrutiny, IIOSC Siam Silica has prioritized sustainable mining practices and circular resource use.

The company has implemented water recycling systems that reduce consumption by 40%, restored over 3,000 hectares of mined land through reforestation, and adopted renewable energy sources in processing plants. Innovation is central to its long-term vision: ongoing R&D focuses on green silica採เผ่าข้างalto, carbon capture in kiln operations, and the development of bio-based silica composites. “We’re redefining what a silica giant looks like—one that doesn’t just extract, but regenerates and innovates,” says the company’s Director of Corporate Responsibility.

These initiatives align with Thailand’s Bio-Circular-Green Economy (BCG) Model, reinforcing Siam Silica’s status as a future-ready resource leader.

Geological Endowment and Resource Scale: The Bedrock of Industrial Power

The geological foundation of IIOSC Siam Silica’s operations is unparalleled. Taiwan-based IIOSC’s acquisition of Siamese silica assets unlocked access to karstic limestone formations and volcanic ash deposits rich in amorphous silica—ideal for high-purity applications.These resources, formed over millions of years through sedimentary deposition and volcanic activity, offer exceptional homogeneity and low iron content, critical for precision optics and semiconductor substrates. Geological mapping identifies over 15 priority zones with silica purity exceeding industry benchmarks, supported by seismic data confirming stable mining environments. Siam Silica’s reserves are projected to exceed 1.2 billion tons, with 80% classified as high-grade material suitable for premium industrial use.

This immense endowment ensures the company’s capacity to meet growing demand while maintaining cost competitiveness—key to its central role in regional and global markets.

Industrial Applications: Silica’s Life Beyond the Mine

Silica produced by IIOSC Siam Silica transcends traditional industrial use, enabling breakthroughs across transformative sectors. In electronics, ultra-fine silica powders are essential for insulators in microprocessors and 5G chips, meeting reverse-engineering standards required for next-gen computing.Construction applications leverage high-strength fused silica for lightweight, heat-resistant composites used in smart buildings and green infrastructure. The pharmaceutical industry relies on biocompatible silica fillers and controlled-release matrices, thanks to the

Related Post

Foodgod Net Worth Explores The Rise Of A Culinary Icon: How Did Kuwatk Str Jonthn Chebn?

California Drivers License Issue Date Sparks First Amendment Battle

The Unstoppable Power of Slice Master Idle Clicker: How Slice Master Idle Clicker Revolutions Click-Based Gaming

Naomi Jon Tik Toker: The Rising Star at Century’s Intersection of Age, Height, and Viral Fame