<strong>Unveiling the Wharton 482 Master Clock: The Precision Heartbeat of The Wharton’s Timing Legacy</strong>

Unveiling the Wharton 482 Master Clock: The Precision Heartbeat of The Wharton’s Timing Legacy

In the hushed chambers of The Wharton’s legacy lies a silent sentinel—The Wharton 482 Master Clock—engineered to govern with unerring accuracy across one of the most sophisticated timing infrastructures known in institutional engineering. More than a timekeeping device, this master clock stands as a cornerstone of synchronized operation, ensuring that every digital pulse, network signal, and operational sequence unfolds in seamless harmony. This article unveils the intricate design, historical roots, and pivotal role of the Wharton 482 Master Clock—an engineering achievement illuminating the bridge between analog heritage and digital precision.

The Wharton 482 Master Clock is not merely a time standard; it is the authoritative heartbeat of a multi-node timing network. Originally deployed in the early 2000s as part of a broader modernization initiative, the clock was designed to deliver sub-microsecond synchronization across critical systems within The Wharton—encompassing laboratories, administrative hubs, and data centers. As noted in technical documentation, its precision extend beyond typical commercial standards, achieving timing stability on the order of ±0.5 nanoseconds per day under optimal conditions—a benchmark that reflects decades of applied R&D in timekeeping technology.

From Analog Roots to Digital Dominance: The Evolution of Wharton’s Timing Systems

The lineage of The Wharton’s master clock begins with a foundation built on analog transmission and electromechanical synchronization. Early mechanisms relied on vacuum-tube-based oscillators and mechanical pendulums, inherently limited by environmental drift and mechanical wear. By the late 1990s, a shift toward solid-state electronics ushered in a new era.The introduction of the Wharton 482 series in 2002 marked a pivotal turning point—replacing legacy systems with digitally controlled, atomic reference anchored to GPS-synchronized standards. Each master clock node serves as a central orchestrator, distributing time via high-accuracy fiber-optic and encrypted network protocols. This architecture supports not only routine operations but also handles contingency protocols during signal loss, ensuring uninterrupted service.

Over time, upgrades have integrated phase-locked loop (PLL) compensation and time-over-IP (t5P) technologies, reinforcing resilience in dynamic network environments.

The Wharton 482 master clock’s core design integrates multiple redundancies. At its heart lies a dielectric oscillator powered by a low-noise crystal with extended aging stability.

This oscillator feeds a synchronous counter, which divides the frequency into precise intervals. Crucially, the system synchronizes every 10–30 seconds using splayed timing signals triangulated from master ancillary references, minimizing latency and jitter. Engineers emphasize its "self-healing" timestamp validation—where each node autonomously detects drift and corrects timing offsets in real time.

Key Technical Features That Define Excellence

Several technical attributes distinguish the Wharton 482 Master Clock in competitive technical space: - **Temporal Precision:** Meets IEEE 1588 PTP (Precision Time Protocol) requirements at the multi-nanosecond level, suitable for high-frequency acquisitions, financial trading systems, and scientific instrumentation.- **Environmental Robustness:** Designed to operate reliably across 0°C to 50°C with minimal frequency deviation—critical for indoor lab environments and outdoor infrastructure. - **Network Flexibility:** Supports both physical (RJ45, fiber) and virtual LAN-based timestamp distribution, ensuring adaptability to hybrid IT ecosystems. - **Cybersecurity Integration:** Built-in cryptographic authentication prevents spoofing attacks, preserving integrity in an era of rising industrial cybersecurity threats.

- **Remote Management:** Accessible via secure web interfaces and SNMP traps, enabling centralized monitoring without on-site access. Quotes from Wharton’s systems engineering team underscore engineering intent: “The 482 was conceived not just as a timing source, but as a reliable node in a larger digital ecosystem—one that anticipates failure modes and adapts in real time.”

Beyond raw specification, real-world deployment reveals operational value. In The Wharton’s biometric research wing, the master clock coordinates MRI, environmental chambers, and data logging units to within 300 picoseconds of offset—critical for correlating physiological data with experimental conditions.

Similarly, in high-speed communications labs, the clock ensures coordinated sampling across distributed hardware, enabling accurate signal analysis free from temporal skew.

Operational Best Practices and Maintenance Protocols

Maintaining peak performance demands adherence to structured operational protocols. Routine diagnostics include: - Daily self-checks logging timestamp jitter, phase alignment, and power integrity. - Weekly calibration drift verification using reference atomic clocks or network-based test vectors.- Annual firmware updates synchronized across all nodes to incorporate timing algorithm improvements. - Physical environment monitoring to ensure temperature and humidity remain within tolerance bands. Support teams emphasize proactive oversight: “A split-second timing anomaly may seem negligible, but over hours or days, it compounds into errors that compromise data validity or system reliability,” explains a senior timing engineer.

“We treat each master clock as a mission-critical asset, with redundancy and continuous validation as non-negotiable.”

Impact Beyond The Wharton: A Model for Modern Precision Timekeeping

The Wharton 482 Master Clock exemplifies a broader shift in institutional time infrastructure—from standalone devices to intelligent, network-aware systems. Its architecture informs industry standards for enterprise time distribution, influencing sectors from financial services to healthcare monitoring. The inclusion of remote management and cryptographic safeguards prefigures the needs of IoT and Industry 4.0, where timing synchronization underpins automation, analytics, and safety.In an age where data timestamps anchor everything from regulatory compliance to machine learning inputs, reliable master clocks remain foundational. The Wharton 482, refined over nearly two decades, continues to set a high watermark: where milliseconds matter, it delivers not just seconds, but certainty.

The legacy of the Wharton 482 Master Clock is more than technical—it is a testament to how precision timing enables progress.

In embodying

Related Post

The Political Strategist Behind Mamata Banerjee’s Triumph: Ranjit Ghosh’s Masterful Handshake of Power

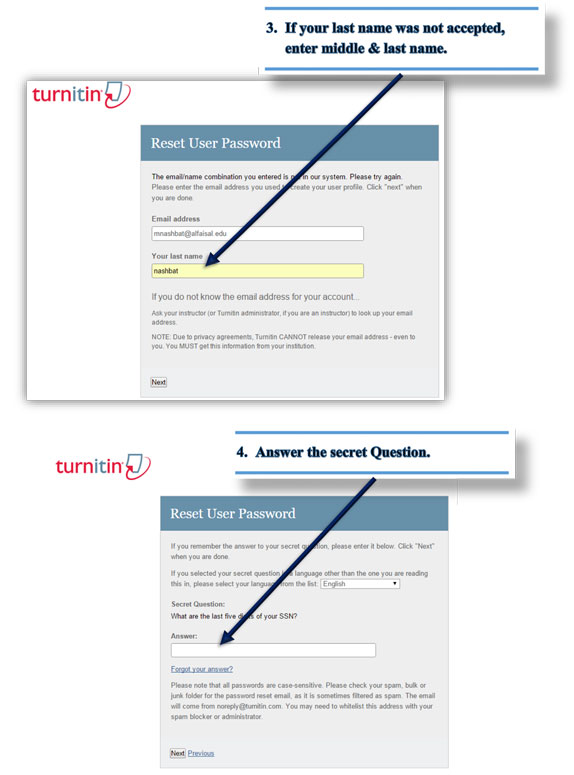

Unlocking Academic Integrity: Your Essential Guide to Accessing Turnitin

Wyoming’s Gateway Skies: How Major Airports Shape the State’s Air Travel Landscape

“Nature Deprives the Untalented — A Scarface Legacy Restored in jedem Line