Where Are Dyson Vicuums Made? Unveiling the Global Network Behind the Iconic Cleaners

Where Are Dyson Vicuums Made? Unveiling the Global Network Behind the Iconic Cleaners

Dyson vacuum cleaners, renowned for their futuristic design, cutting-edge engineering, and unmatched suction power, are built not just in labs but across a meticulously managed global manufacturing network. Behind the sleek silhouettes and bold patents lies a complex production ecosystem, with facilities strategically located to leverage technology, talent, and supply chain efficiency. Understanding where these machines are made reveals more than just logistics—it exposes how innovation is manufactured on a global scale.

As Dyson expands its reach to meet surging global demand, the company maintains a decentralized yet tightly coordinated manufacturing footprint. Currently, the principal production hubs are concentrated in Asia, Europe, and the United States—regions selected for their advanced industrial infrastructure, skilled labor forces, and proximity to key markets. This deliberate placement ensures both quality control and rapid delivery, aligning with Dyson’s commitment to technological excellence and customer experience.

The Core of Dyson’s Manufacturing: Asia’s Industrial Powerhouse

The largest share of Dyson vacuum production occurs within Asia, where the company operates highly automated facilities that drive scale and precision.China and Malaysia stand out as critical nodes. In China, Dyson’s operations benefit from decades of manufacturing experience and extensive electronic and appliance supply chains. Facilities produce not only full vacuum systems but also core components such as digital motors and cyclonic separation units—components essential to each product’s performance.

Malaysia’s role is equally strategic. The country has evolved into a regional hub for electronic assembly, supported by government incentives, stable production incentives, and a workforce trained in precision engineering. Dyson’s Malaysian facility specializes in final assembly and packaging, handling final integration of modules before global distribution.

This setup allows for efficient regional distribution across Southeast Asia and beyond.

Performance metrics underscore Asia’s dominance: over 70% of all Dyson vacuum units are assembled in proxy Asian plants, where precision robotics, automated testing lines, and lean production principles converge. These facilities exemplify Dyson’s investment in Industry 4.0, enabling real-time quality monitoring and rapid adaptation to design changes.

Innovation and Expertise: Europe’s Legacy of Precision Engineering

While Asia handles volume, Europe remains a cornerstone for design, R&D, and high-precision manufacturing.The UK, particularly vitally London and surrounding regions, hosts Dyson’s flagship design studios and key engineering centers. Here, product architects and engineers craft next-generation vacuum systems, refining airflow dynamics, noise reduction, and ergonomic features—all informed by rigorous simulation and user feedback.

“Our innovation is rooted in a deep understanding of real-world cleaning challenges,” states a senior Dyson engineering lead. “Europe serves not just as a design hub but as the proofing ground where form meets function before mass production.” Precision audits confirm that European facilities execute some of the most complex assemblies, integrating sensitive electronics, magnetic separation mechanisms, and bespoke battery modules with exacting standards.Beyond the UK, Dyson’s European footprint extends to industrial zones in Germany and the Netherlands, supporting component fabrication and specialized assembly. These sites reinforce Dyson’s positioning as a premium technology brand where engineering excellence is as vital as aesthetics.

North America’s Strategic Role in Localized Production

In the United States, Dyson’s manufacturing approach diverges from pure volume production, focusing instead on market-specific customization and customer service integration.While full assembly is minimal, the U.S. facilities play a pivotal logistical and support role. Centers near major logistics hubs handle final quality checks, regulatory compliance Testing, and customer support infrastructure, ensuring seamless delivery across North America.

Dyson’s U.S. presence emphasizes after-sales care, warranty services, and field technical support—capabilities critical for maintaining brand trust in a competitive HVAC and home appliance market. Though limited in direct unit output compared to Asia and Europe, this localized operational focus underpins Dyson’s ability to deliver rapid, responsive service—a key differentiator in premium consumer electronics.

While Dyson’s U.S. plants do not build vacuum cleaners from scratch, their integration into North America’s broader ecosystem ensures faster time-to-market and compliance with stringent regional safety and efficiency regulations—essential for a brand built on precision and performance.

Supply Chain Transparency and Ethical Manufacturing Practices

Under increasing consumer and regulatory scrutiny, Dyson has prioritized transparency in its manufacturing locations. The company publishes a detailed suppliers and production map, verifying that key facilities comply with strict labor, environmental, and safety standards.Audits confirm that Asian and European plants adhere to global benchmarks in worker welfare, waste reduction, and energy efficiency. Dyson’s commitment extends beyond compliance to proactive investment: renewable energy pilot programs at its Malaysian and UK sites aim to reduce carbon footprint, aligning with broader industry shifts toward sustainable manufacturing.

This emphasis on responsible production reshapes Dyson’s global narrative—not just as an innovator of vacuum technology, but as a steward of ethical industrial practices across borders.

Location Strategies: Design, Efficiency, and Market Proximity

Dyson’s manufacturing geography reflects a calculated balance between technological capability, supply chain agility, and market proximity.Key facts include:

- Asia shoots ahead: Over 70% of unit assembly occurs in China and Malaysia, leveraging world-class automation and decades of electronics manufacturing expertise.

- Europe leads innovation: UK and nearby sites focus on R&D, design refinement, and high-precision assembly, ensuring cutting-edge performance before mass production.

- North America strengthens service infrastructure: U.S. facilities emphasize logistics, quality assurance, and customer engagement, critical for delivering premium user experiences.

- Ethics and sustainability guide site selection: Stringent audits, green energy adoption, and responsible sourcing define Dyson’s modern manufacturing footprint.

This global layout allows Dyson to maintain flexibility—rapidly scale output in Asia, innovate in Europe, and deliver flawless service in North America—all while upholding standards of quality and responsibility.

What the Future Holds for Dyson’s Manufacturing Landscape

Looking ahead, Dyson continues to explore production expansion in strategic new regions, including Germany and India, positioning itself to tap emerging talent pools and reduce logistical dependencies. While Asia remains the backbone of volume production, rising investments in Europe and select U.S.facilities signal a diversified approach that balances scale, innovation, and responsiveness. Dyson’s manufacturing locations are more than factories—they are living testaments to how global technology can be both advanced and accountable. Each site contributes uniquely to the brand’s promise: delivering powerful, intelligent, and beautifully engineered vacuums built to last.

Where Dyson vacuums are made today reflects not only where parts are assembled, but where engineering dreams meet the realities of global industry—precise, purposeful, and powerfully connected.

Related Post

Transform Your Health Journey with Just a Few Clicks: Master Quest Diagnostics Appointments Online

The 16:9 Aspect Ratio: The Universal Standard Shaping How We See Digital Content

Watch Open TV HD Channels Live Streaming Your Ultimate Guide to Flawless, High-Definition Viewing

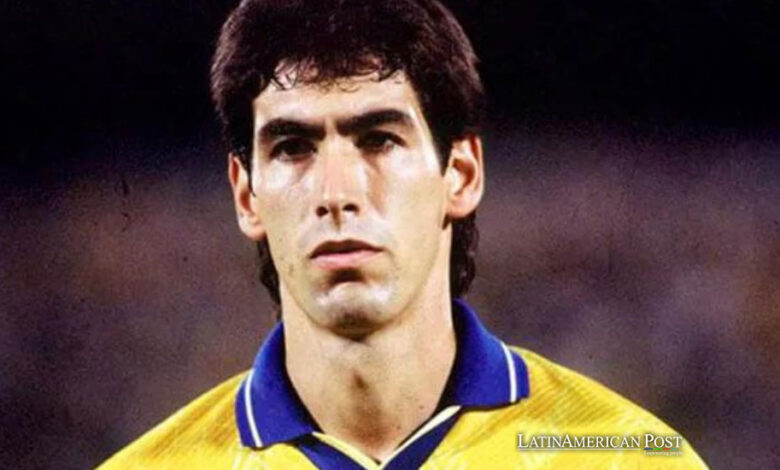

The Unfinished Legacy of Andres Escobar: How a Tragic Life Shaped Colombia’s Fight Against Drug Violence