Why Limiting Reagents Decide Success in Chemical Reactions

Why Limiting Reagents Decide Success in Chemical Reactions

When chemical reactions unfold in beakers and labs, precision governs outcomes. At the heart of this precision lies the concept of a limiting reagent — the substance that dictates the maximum yield of a product before reactants are fully consumed. Without identifying the limiting reagent, even the most carefully calibrated experiment risks wasting resources and delivering inconsistent results.

Understanding this principle transforms chemical problem-solving from trial and error into a strategic, reproducible process.

Defined as the reactant that determines the endpoint of a chemical transformation, a limiting reagent is the “bottleneck” molecule in a reaction. Unlike excess reagents, which remain unreacted, or in excess, which may complicate purification, the limiting reagent is entirely consumed, capping the reaction’s extent.

As physical chemist Dr. Elena Torres notes, “The limiting reagent isn’t about how much you add — it’s about who finishes first.” This simple truth underscores its critical role in synthesis, pharmaceuticals, and industrial manufacturing, where efficiency and accuracy are non-negotiable.

The Core Principle: How Limiting Reagents Control Reaction Yields

At the chemical level, every stoichiometric reaction follows a fixed ratio dictated by balanced equations.When reactants combine, they consume one another in proportions that reflect molar relationships. Once one reagent is fully consumed, the reaction halts — not because the remaining compounds remain, but because no atoms remain to form product. This phenomenon separates the limiting reagent from mere excess.

Consider a basic synthesis where 2 moles of compound A react with 3 moles of compound B to form product C. Even if 5 moles of A and 10 moles of B are supplied, only 2 moles of A will be fully used — if B is present in a 1:1.5 ratio. The remaining A becomes the limiting reagent, meaning C can produce no more even though B lingers unused.

This balance defines the theoretical maximum yield: \\[ \text{Maximum product} = \frac{\text{moles of limiting reagent}}{\text{moles consumed per mole of reagent}} \\] This formula, buried in chemistry’s foundational principles, enables scientists to calculate and predict outcomes with confidence.

- Stoichiometry defines limits: Molar ratios from balanced equations pinpoint the theoretical threshold that a reagent must not surpass.

- Excess causes inefficiency: Adding more of a non-limiting reagent increases waste without improving yield.

- Pilot reactions reveal bottlenecks: Laboratory verification often identifies the limiting reagent before full-scale execution.

Each batch’s success hinges on knowing which reagent will run out first — not which one remains.

Real-World Applications: From Labs to Manufacturing Floors

In organic synthesis, chemists design multi-step reactions where intermediates must react completely. A misread reagent’s stoichiometry can cascade into incomplete conversions, requiring reprocessing or risking product failure.Automated synthesis platforms rely on algorithms that model limiting reagent dynamics in real time, reducing human error and accelerating research. Pharmaceutical development exemplifies the stakes. The synthesis of a new antibiotic may require a complex sequence where reagent ratios determine both yield and purity.

As Dr. Maria Chen, a process chemist, explains, “If you don’t identify the limiting reagent early, you’re optimizing based on estimates — and the product may fail at scale.” This early insight saves time, reduces regulatory hurdles, and ensures compliance with stringent quality standards. In bulk manufacturing, limiting reagent analysis directly affects profit margins.

Consider a polymerization process: excess monomer is costly and environmentally unfriendly. By accurately calculating the limiting reagent, manufacturers scale reactions efficiently, minimizing excess material and maximizing throughput. This precision directly translates into sustainable practices and lower production costs.

Beyond efficiency, limiting reagent identification enhances safety. In reactions involving hazardous reagents, knowing how much is truly needed limits exposure risk. Overloading ensures more unreacted, potentially dangerous compounds linger — increasing storage and disposal hazards.

Trusting process chemistry over guesswork secures safer, more controlled laboratories and factories alike.

Practical Techniques for Identifying Limiting Reagents in the Lab

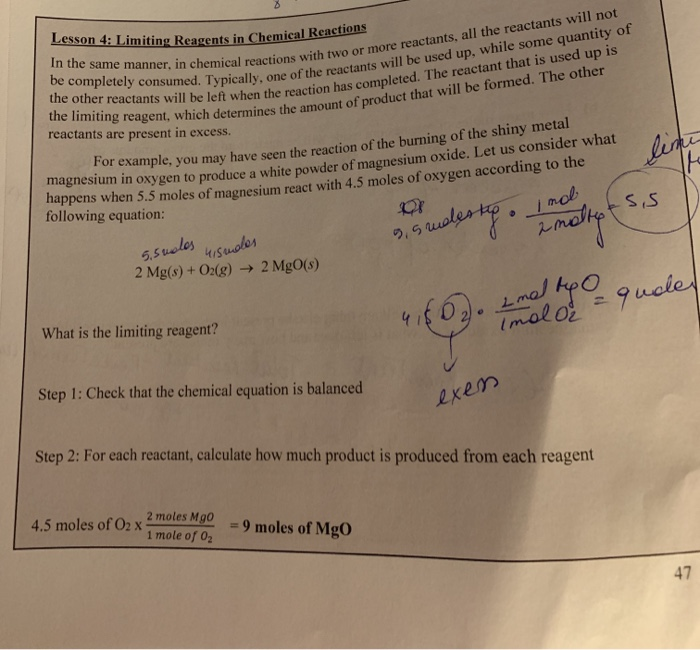

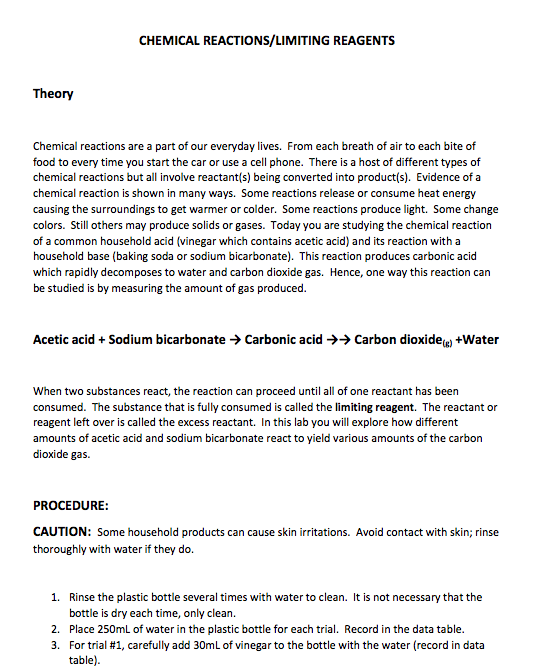

In practice, determining the limiting reagent combines theoretical calculation with experimental verification. Researchers commonly use molar conversions derived from balanced equations to estimate each reagent’s consumption. However, laboratory reality often diverges due to imperfect mixing, side reactions, or impurities.Balancing Equations: Accurate stoichiometric predictions begin with correct reaction equations. Unbalanced formulas misrepresent molar relationships, leading to faulty limits. For example, in a reaction where 2A + 3B → C, assuming 2A fully consumes 3B requires confirming both exist in correct stoichiometric proportions.

Monitoring Reaction Progress: Lab techniques such as spectroscopy, titration, and chromatography track reactant depletion. Analytical data reveal actual conversion rates, exposing whether theoretical limits align with observed results. A drop in reactant concentration faster than expected suggests the corresponding reagent is limiting.

Consecutive Sampling: Scientists periodically sample reaction mixtures to compare initial and remaining concentrations. In a controlled experiment, if B’s concentration halves before A does, B is the limiting reagent. This empirical approach validates predictions and adjusts parameters for improved yield.

These methods, when applied rigorously, empower chemists to anticipate and correct deviations. The limiting reagent is not a theoretical artifact — it’s a measurable benchmark that guides every stage, from concept to production.

The Broader Impact: Precision in Science and Industry

The concept of the limiting reagent transcends laboratory walls, shaping how science and industry innovate responsibly and efficiently. It transforms chemical processes from unpredictable reactions into engineered systems where every molecule counts.In an era demanding sustainability and reproducibility, mastering limiting reagent dynamics isn’t just a technical skill — it’s a strategic imperative. Understanding this principle means recognizing when to push limits and when to retreat — when to increase concentrations and when to halt. It’s a mirror reflecting the true bottleneck in complex transformations, allowing researchers to optimize without overshoot or waste.

Whether in a small academic lab testing novel compounds or a large-scale factory producing millions of dollars’ worth of pharmaceuticals, the limiting reagent’s role remains pivotal. This is the silent architect of chemical progress — invisible, yet indispensable. It ensures reactions proceed with intention, yields are maximized, and resources are used with precision rarely matched elsewhere in science.

As new research and industrial applications emerge, the limiting reagent endures not just as a concept, but as a cornerstone of effective chemistry.

In the end, the true power of a limiting reagent lies not in what it is, but in what it reveals: the exact moment and measure at which a reaction concludes, transforming input into meaningful output with economy and clarity.

Related Post

Top Wireless Mouse Brands: Top Ratings, Expert Reviews, and Real-World Performance

Unlocking Playtime: The Rise and Power of the 5 Dollar Roblox Gift Card

Lawsuit Blurred Lines: The High-Stakes Battle Over Copyright, Creativity, and the “Blurred Blur” of Musical Inspiration

Feyenoord vs Inter Milan: A Clash of Giants—Statistics, Rivalry, and the Pulse of Dutch-Italian Football